Minimum Energy Adaptive Structures

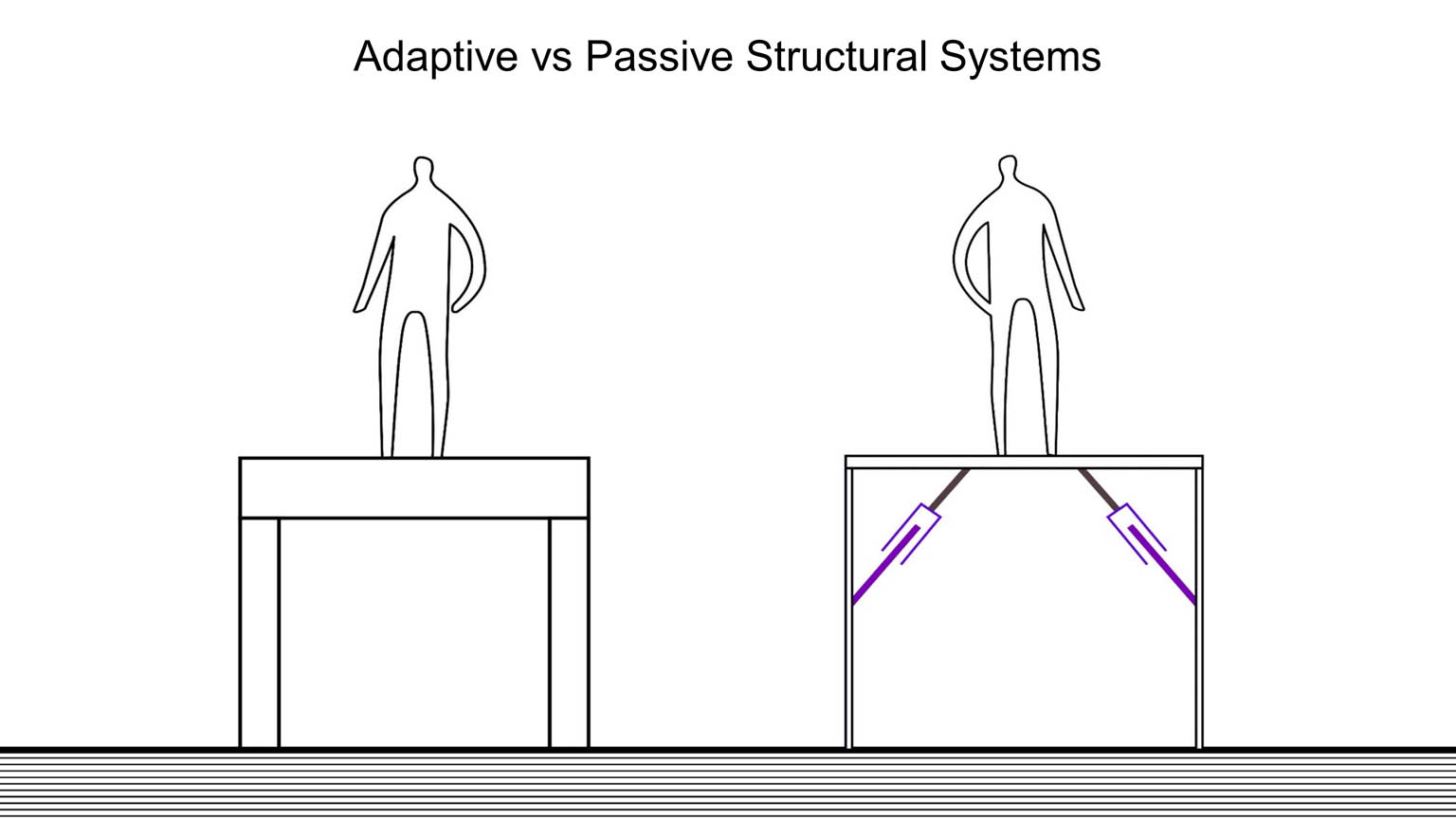

This research uniquely combines structural design with control engineering and sustainability to develop new types of load-bearing adaptive structures that have significantly improved performance as well as reduced environmental impacts compared with conventional passive structural systems.

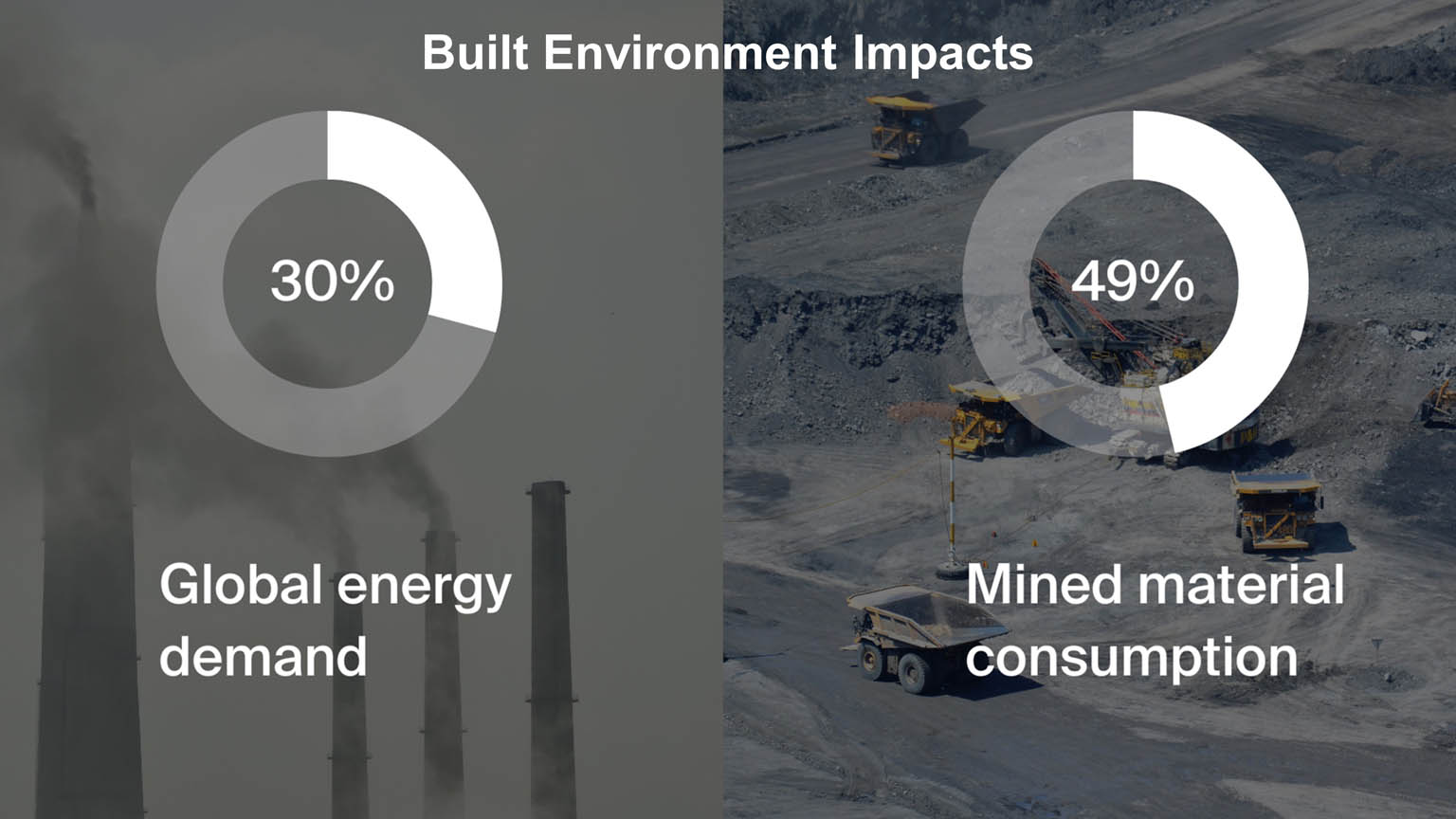

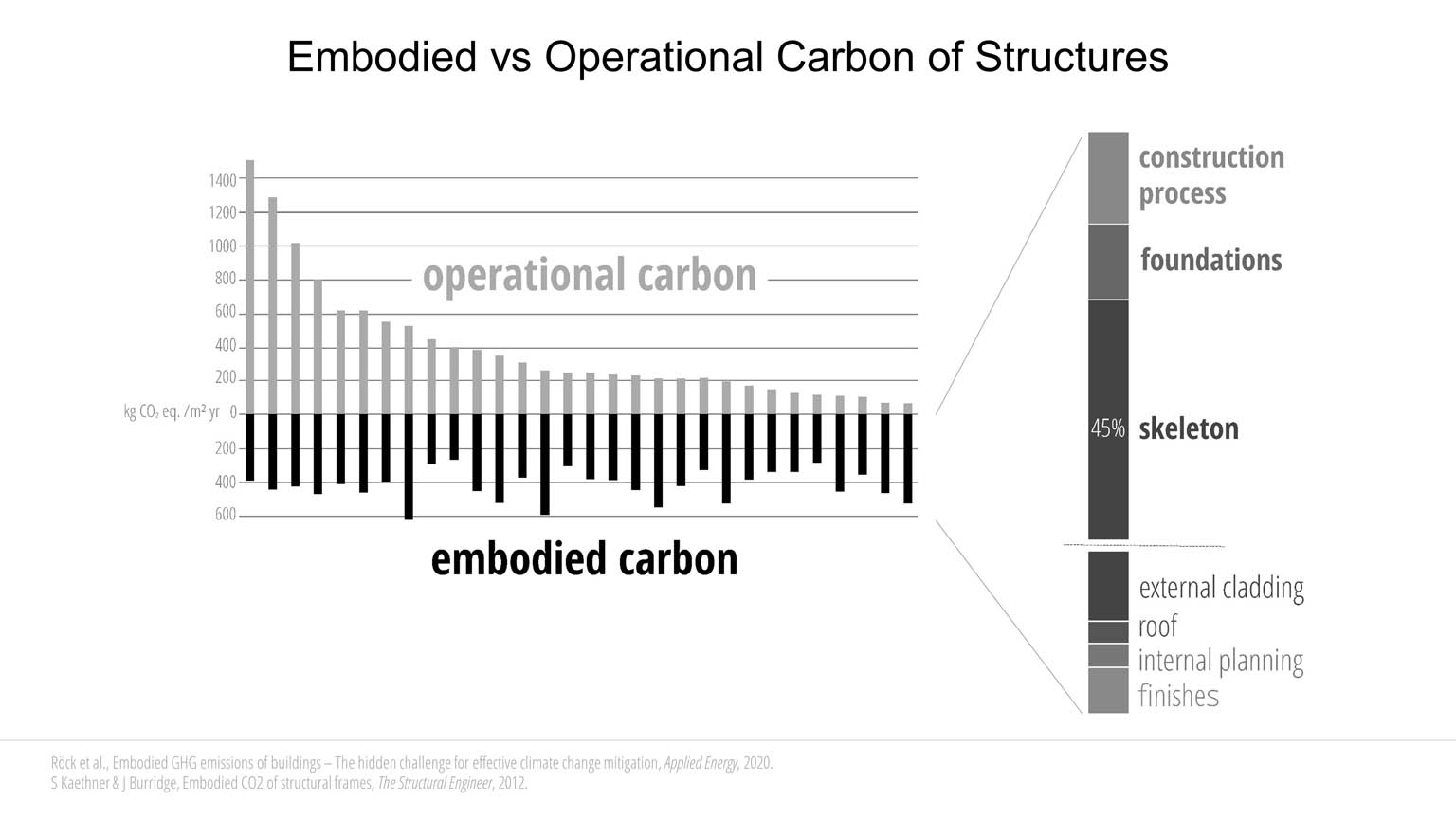

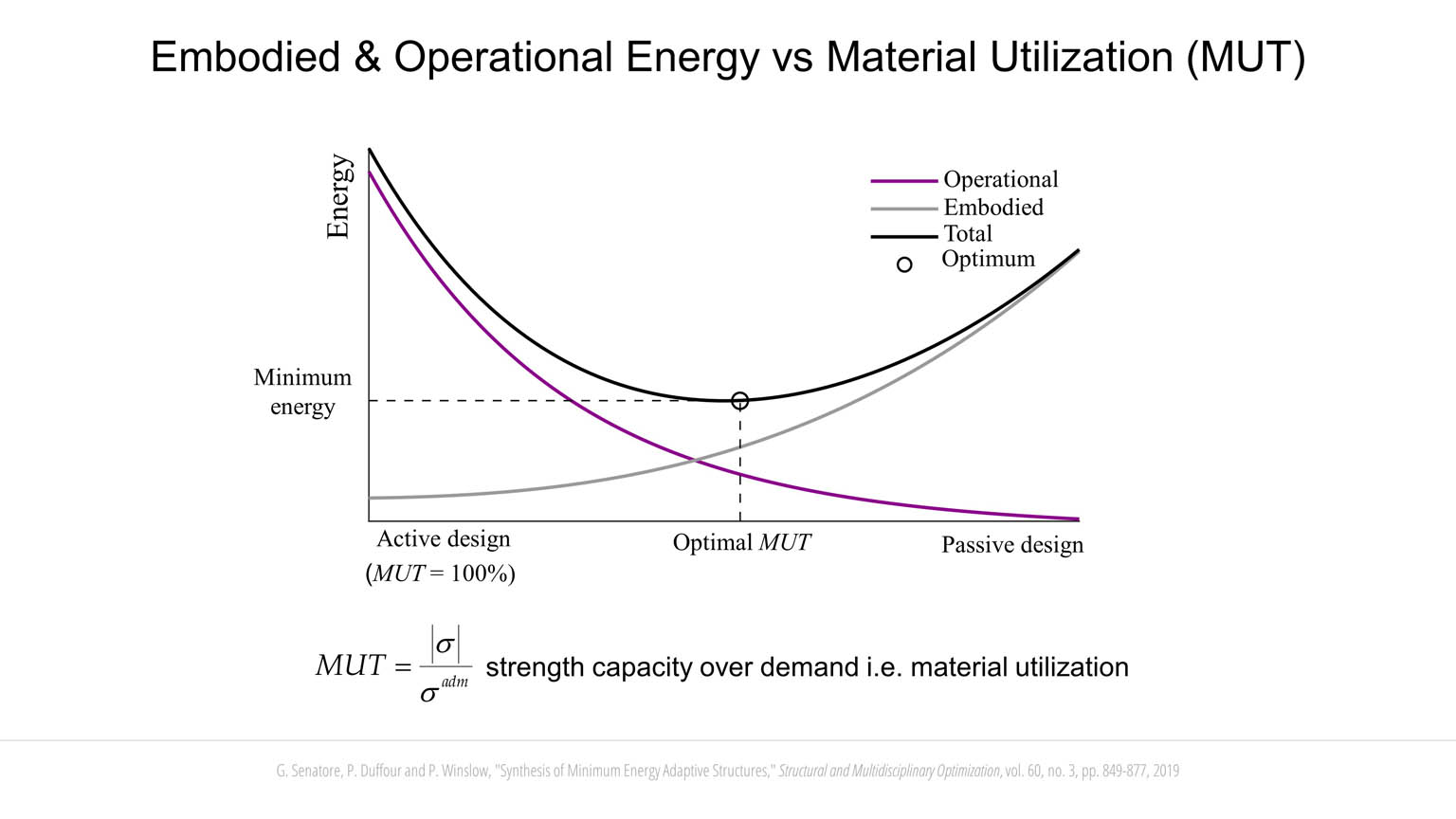

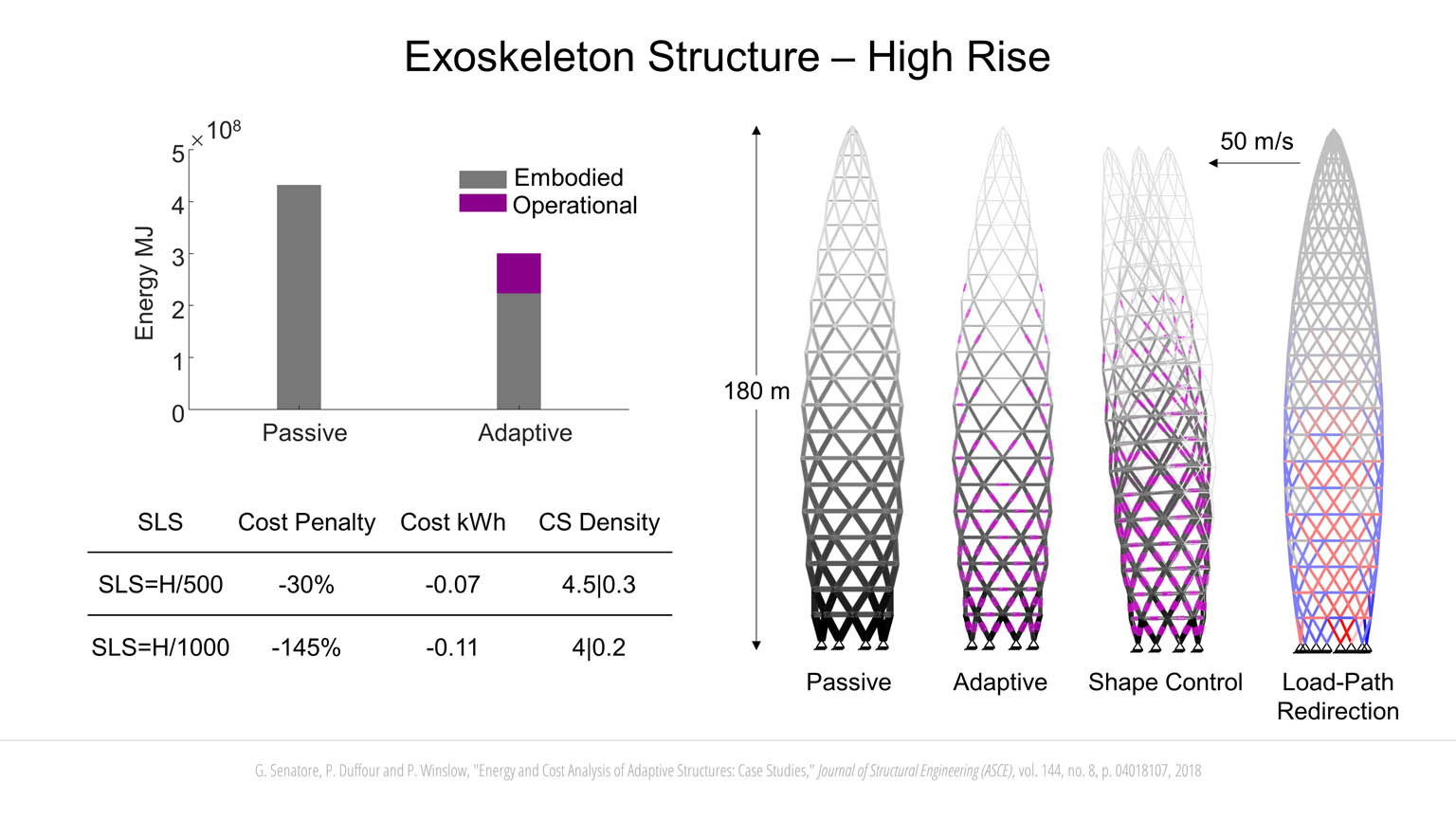

The construction industry is the largest consumer of raw materials and it contributes to more than a third of the global energy demand. Built environments are responsible for up to 40-50% of total carbon dioxide emissions throughout their service life. A significant share of buildings’ and structures’ life-cycle emissions is embodied because it arises from the manufacturing of components, construction, transport, and demolition. Despite this, most civil structures are significantly oversized because they are designed to withstand worst-case loading events such as high winds, earthquakes, heavy snow, and large crowds which in practice occur very rarely. This means that conventional civil structures are typically overdesigned for most of their service life. Instead, if structures can adapt to changing loading conditions, they can operate closer to design limits, which enables material and embodied energy (or carbon equivalent) savings. However, such embodied savings come at a cost of operational energy for adaptation to loading during service.

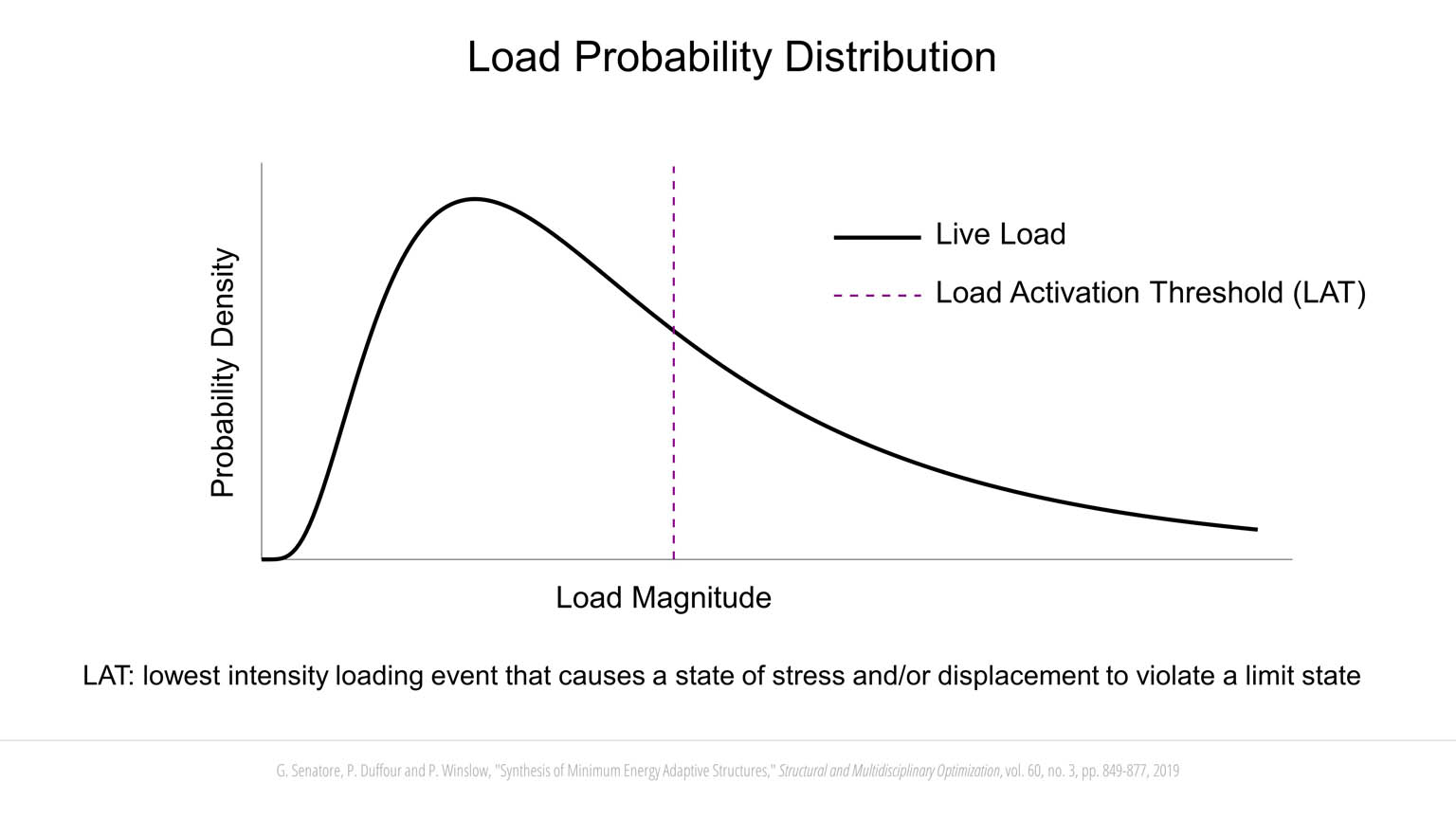

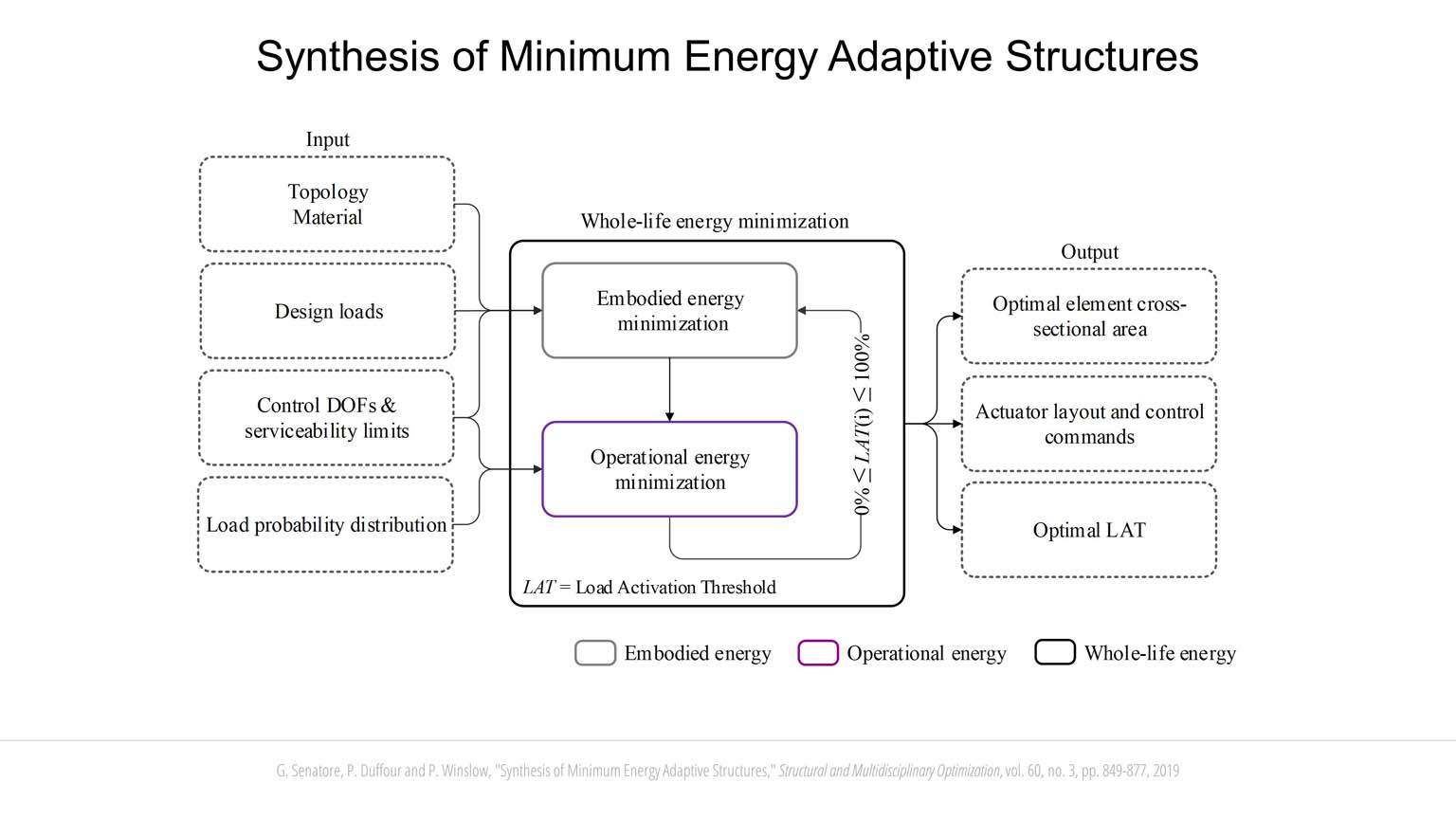

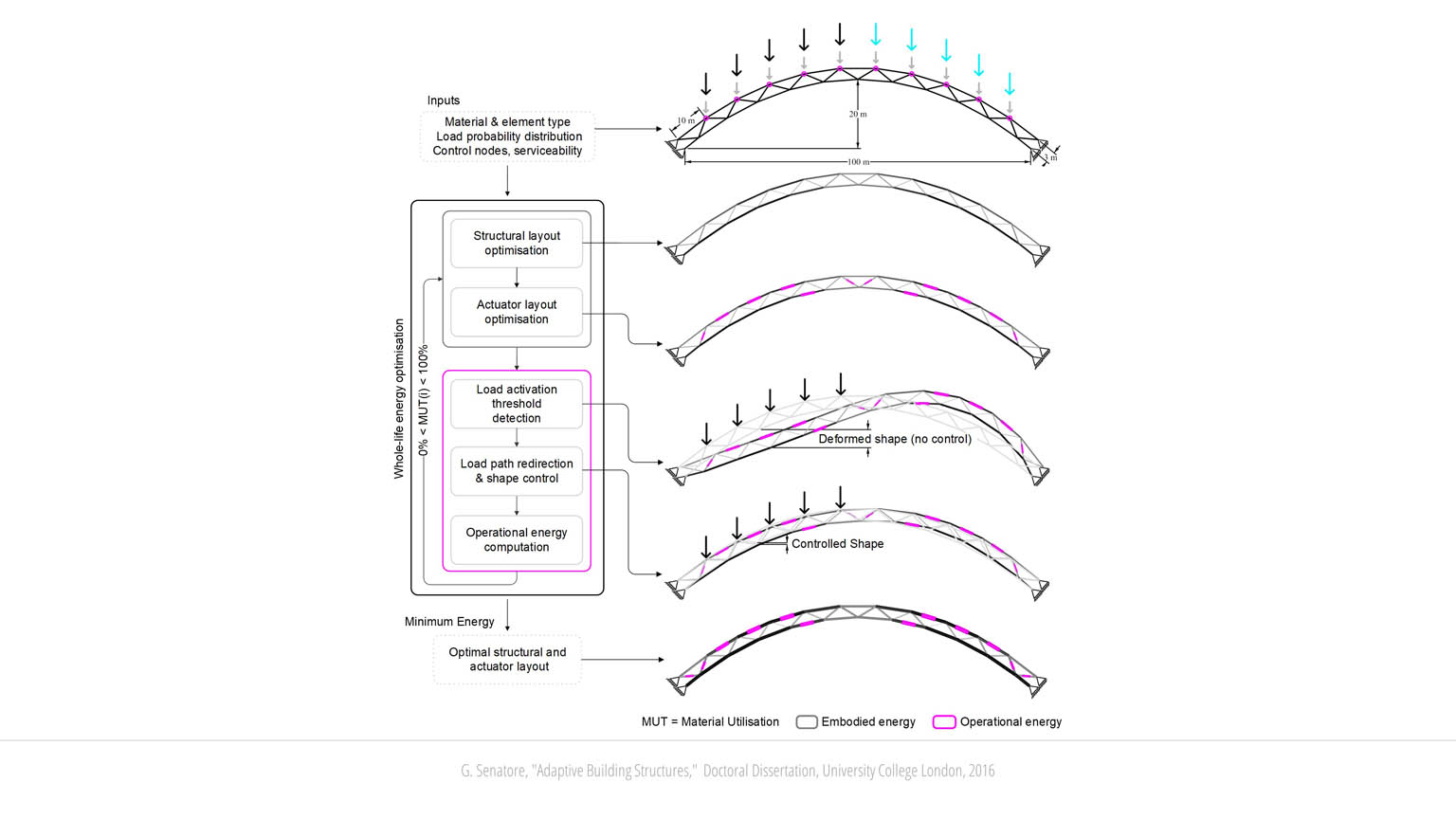

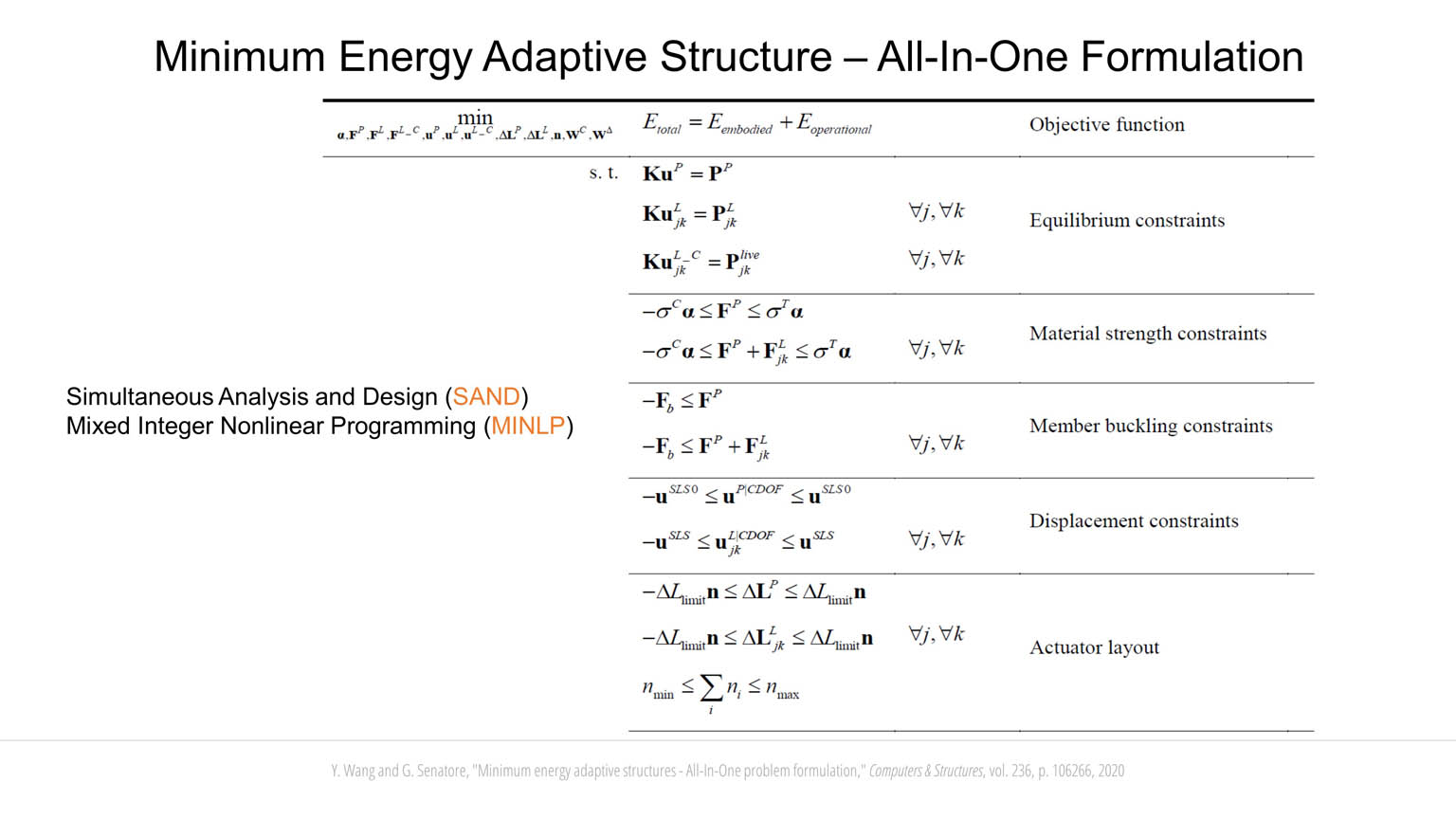

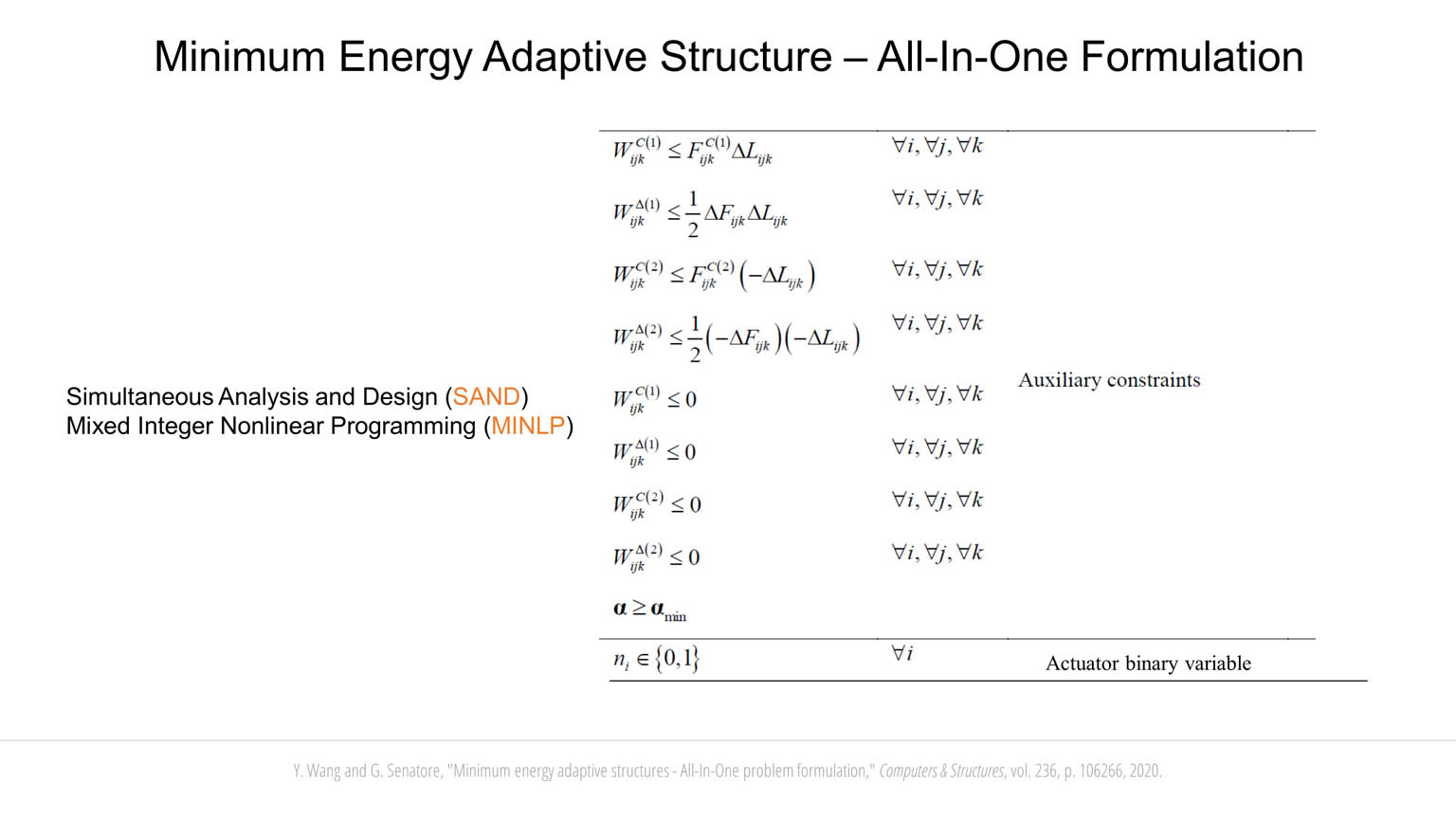

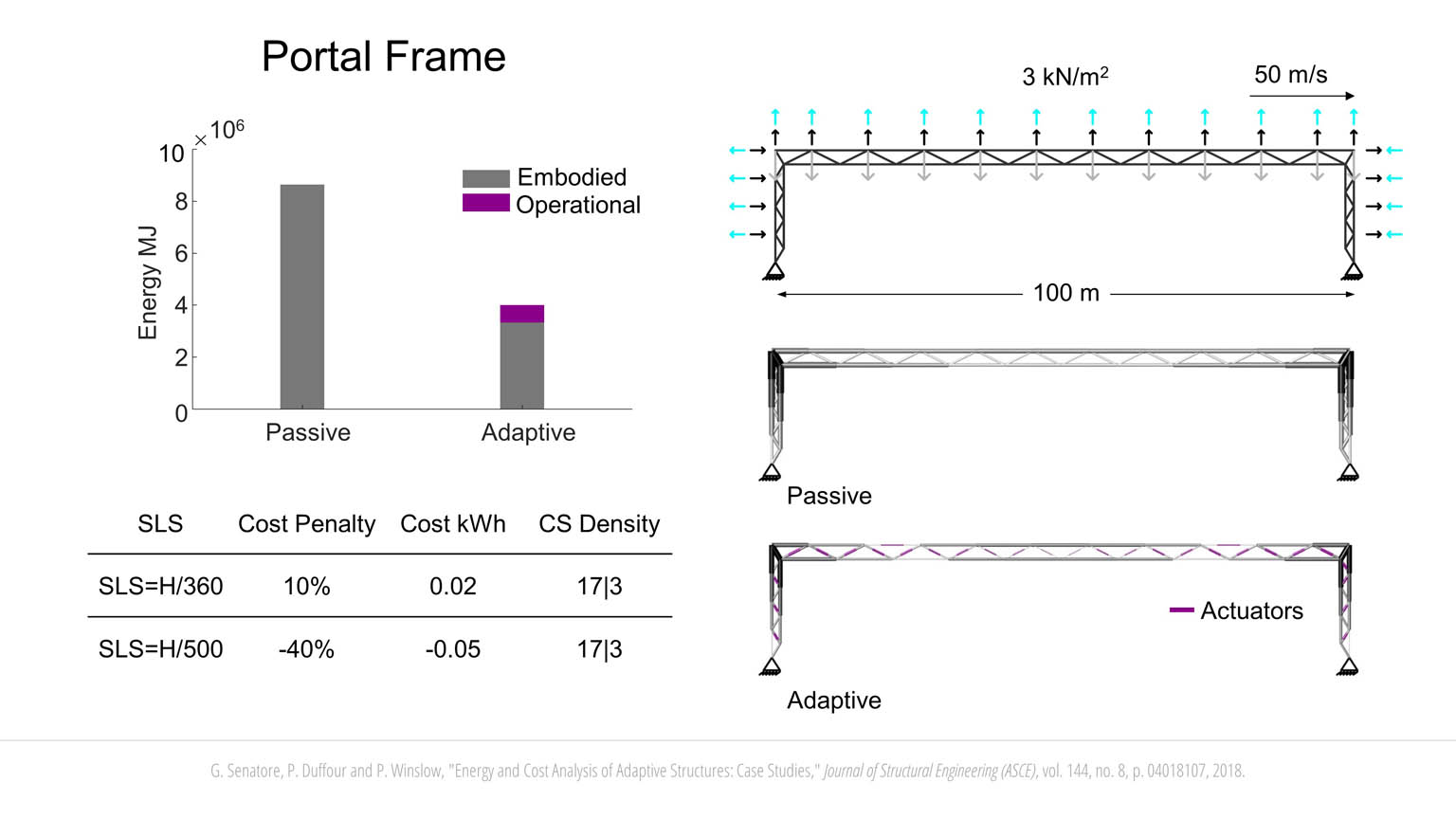

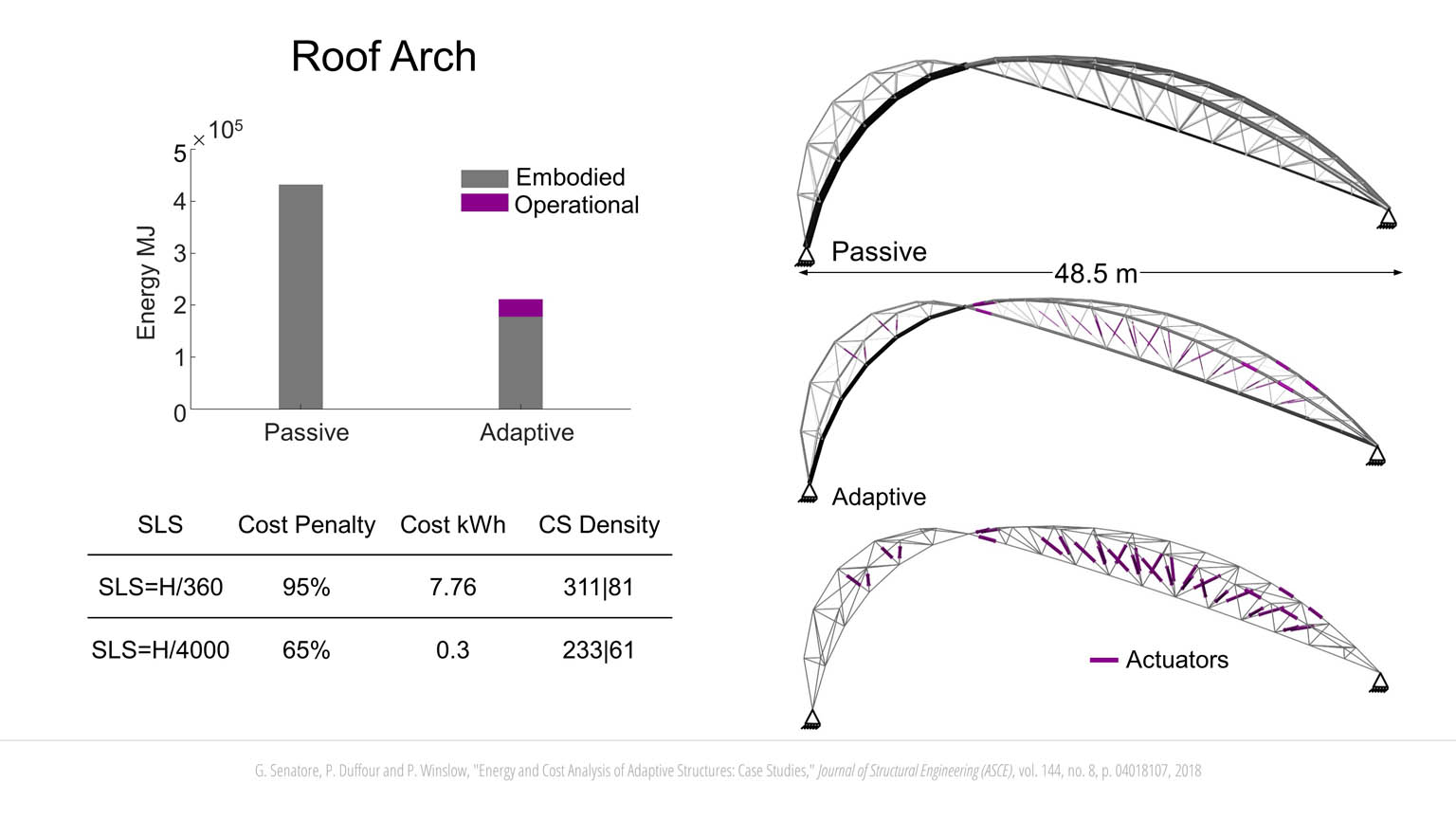

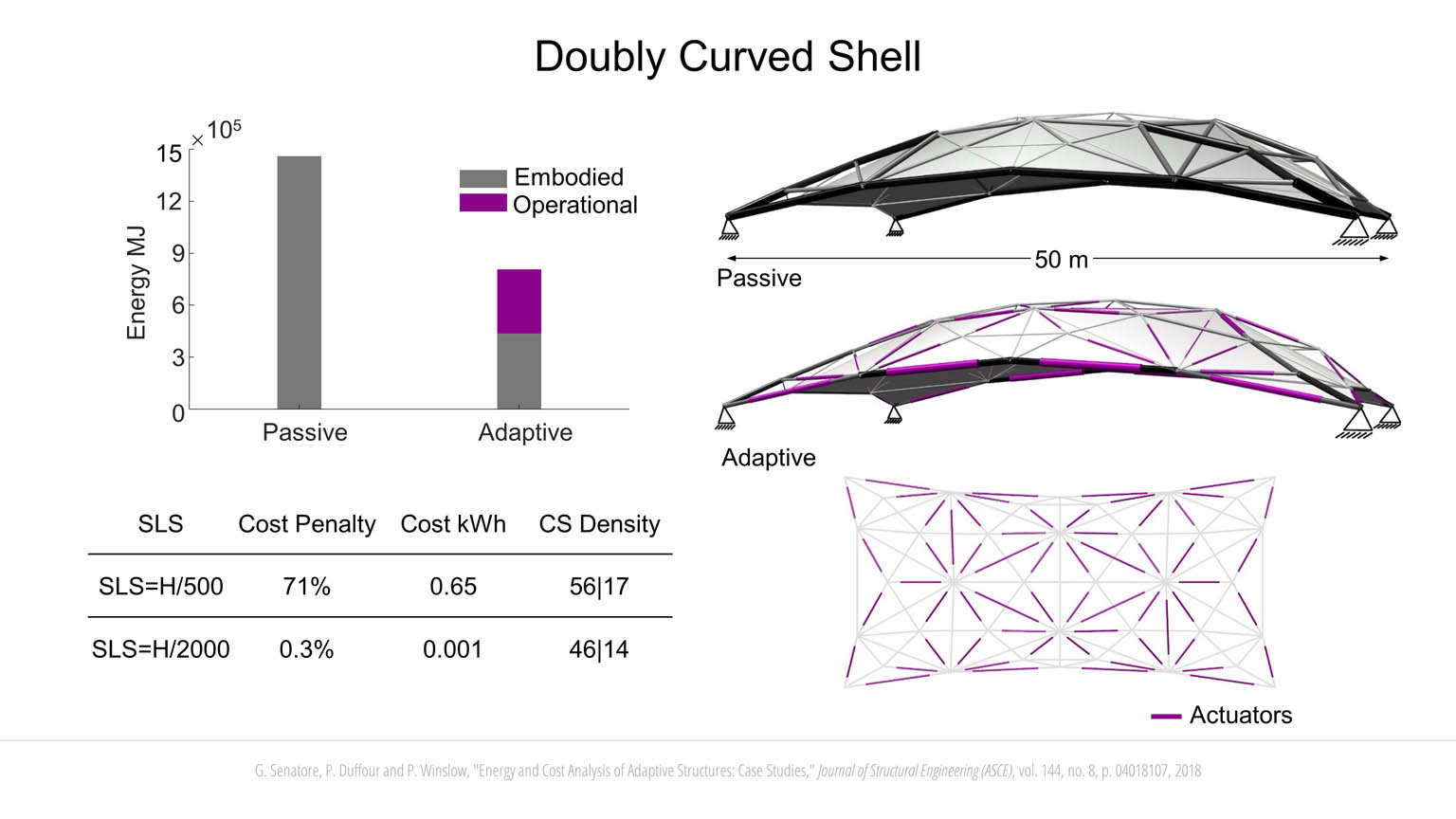

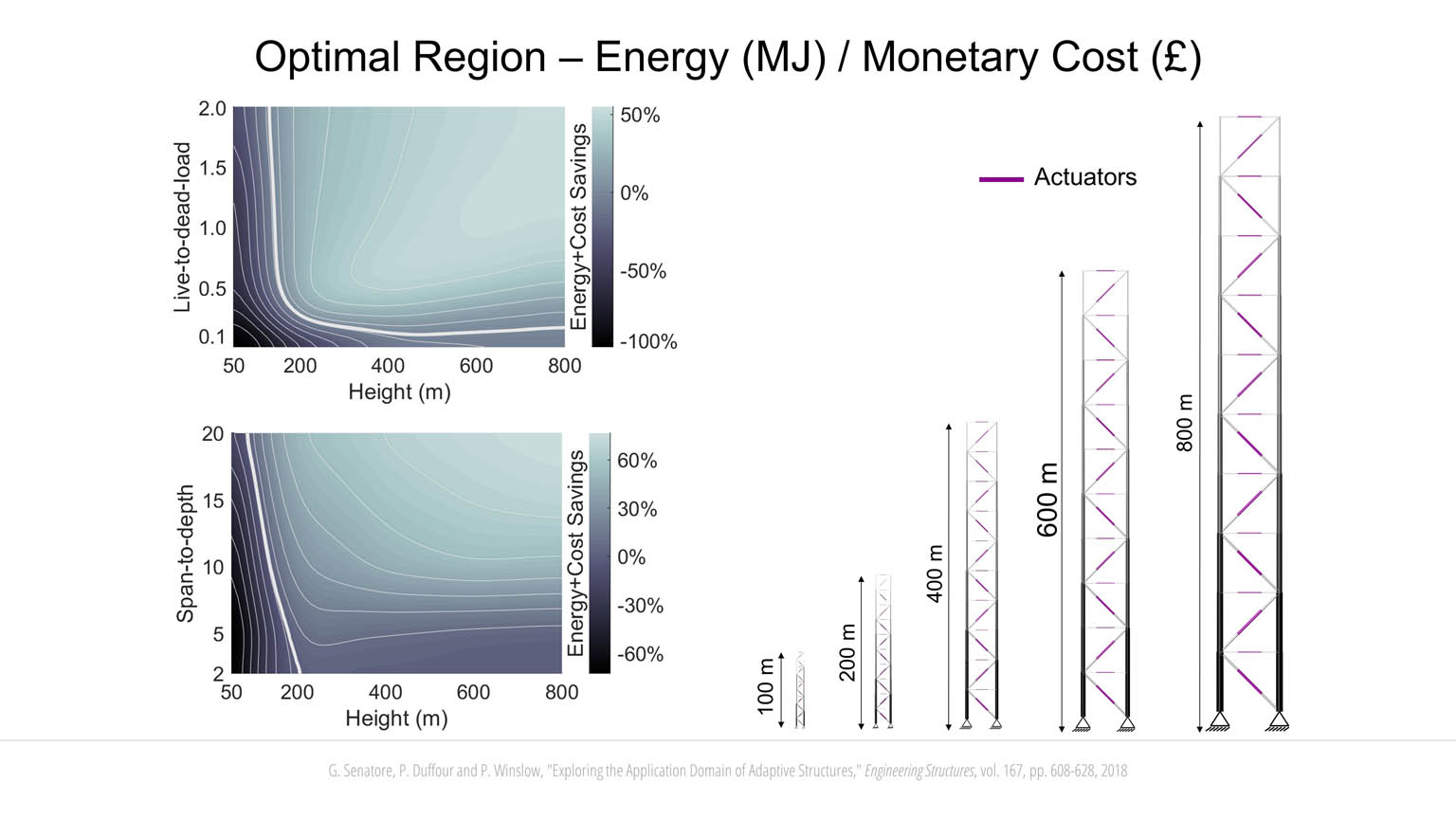

This research has produced new computational methods to design structures equipped with sensing and actuation systems that are able to counteract the effect of loading and other environmental actions through control of internal forces and structural shape. The adaptive solution is designed through simultaneous optimization of structural layout and actuator placement. The design criterion is minimization of whole-life energy (or carbon equivalent) that comprises a part embodied in the material and an operational part for sensing, control and actuation during service. Traditional design goals currently employed, such as life-cycle-cost minimization, do not explicitly address current and future challenges such as material scarcity and energy depletion, thus hindering creative development of strategies to design structures. Whole-life energy minimization encompasses modern design goals that include minimizing material and energy requirements as well as minimizing cost. Whole-life energy minimization is a challenging design problem because it is non-linear, non-convex and mixed-integer. The integrated structure-control optimization methods developed through this research are able to solve this problem efficiently when implemented for large-scale structural systems. To ensure the operational energy required for adaptation is kept to a minimum, the adaptive solution is designed to withstand ordinary loading events using only passive load-bearing capacity while relying on active control to deal with larger events that have a smaller probability of occurrence. In case of a power outage or control system failure and concurrent occurrence of a strong loading event, the structure does not collapse because it is designed to have sufficient carrying capacity even without contribution of the actuation system. In such a scenario, however, serviceability requirements (e.g. deflections) might not be fully satisfied.

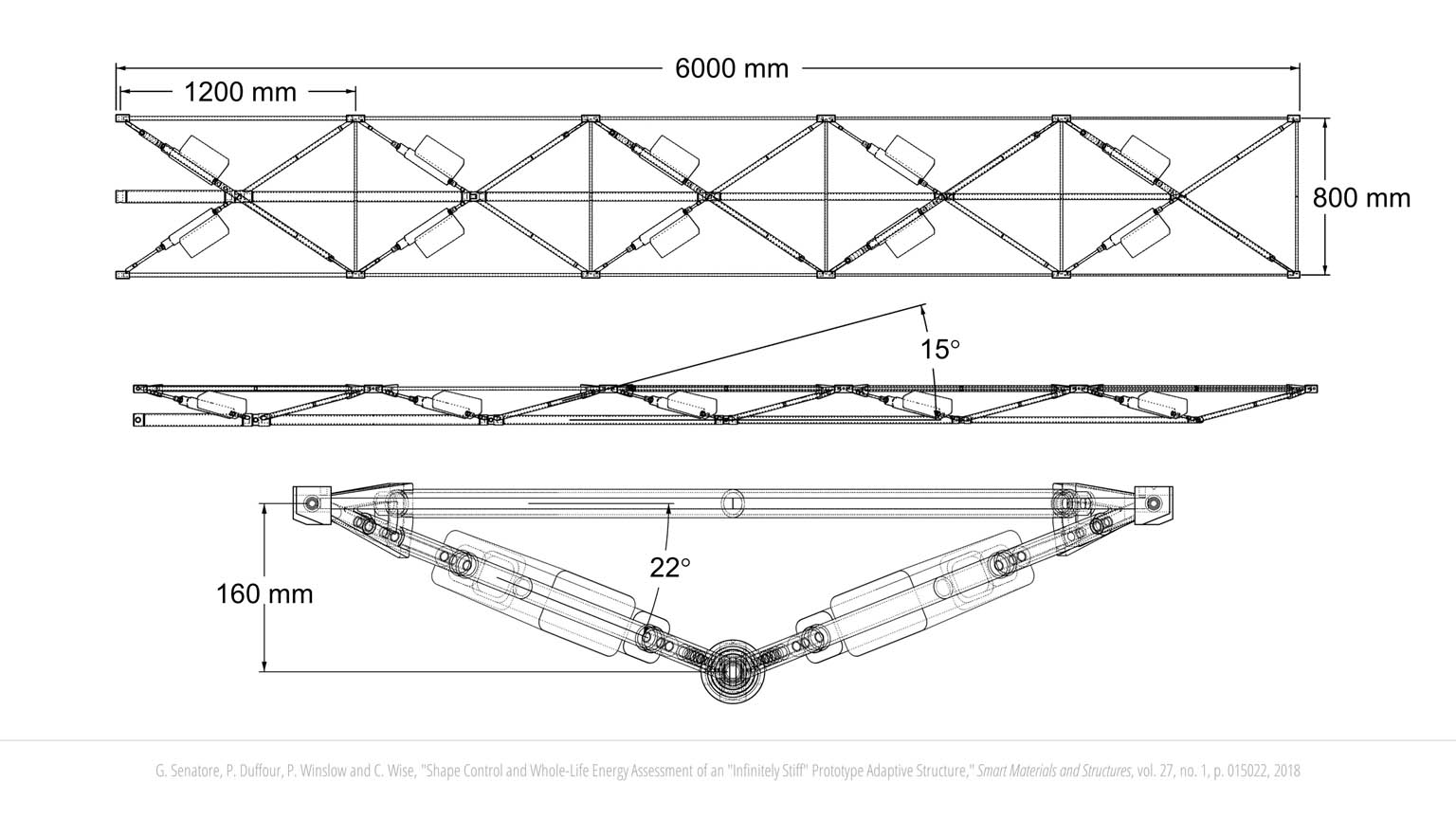

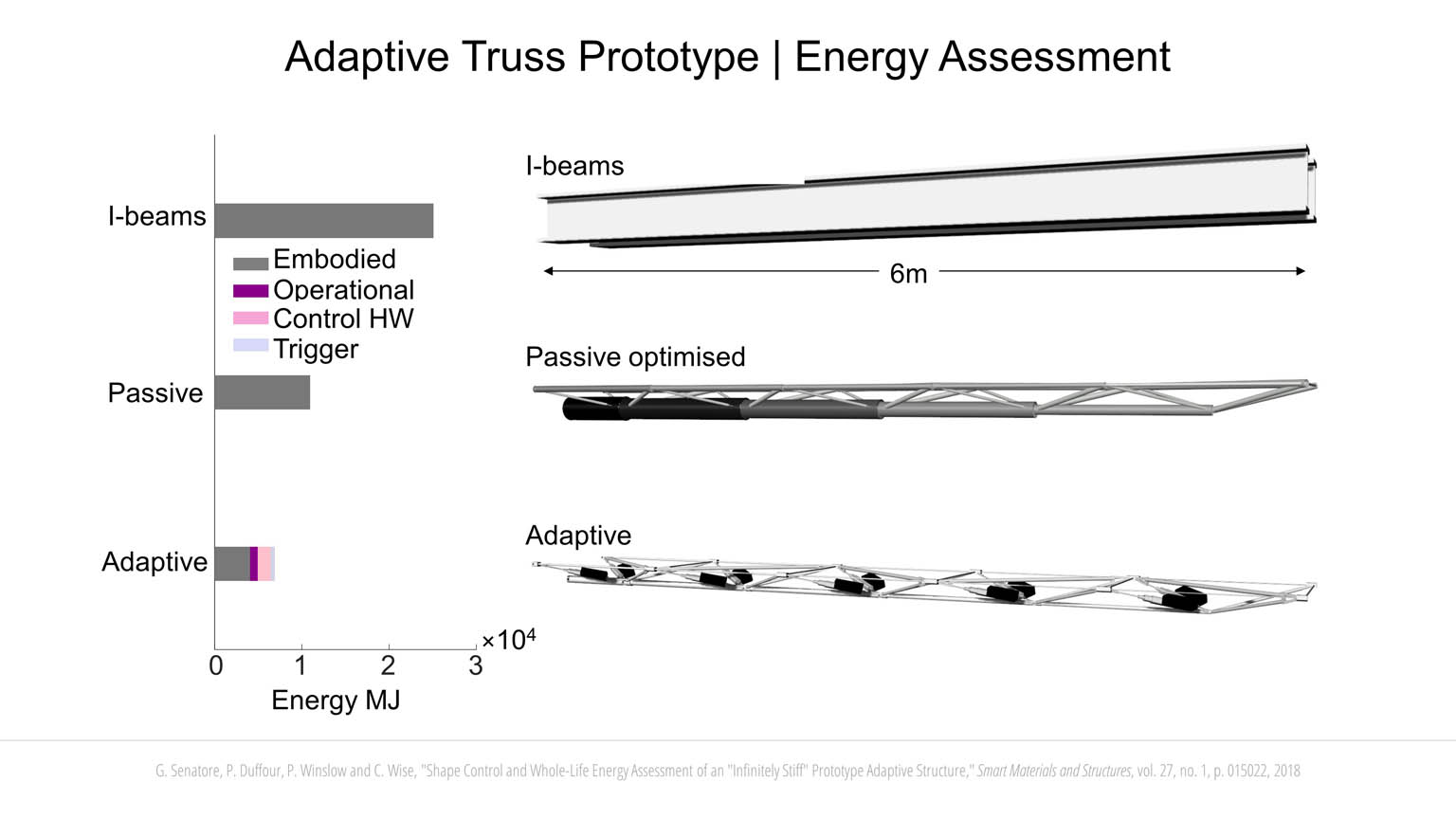

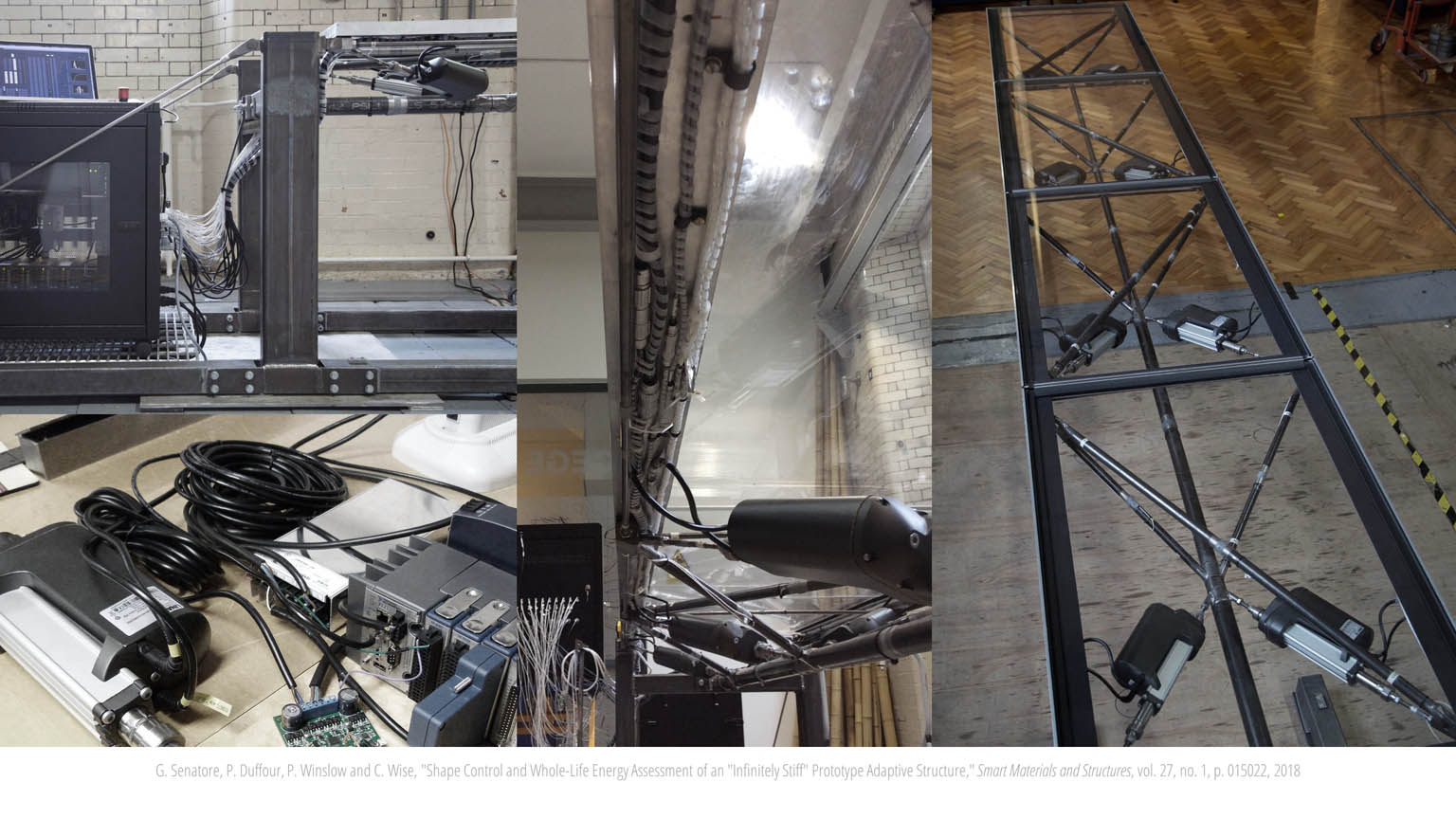

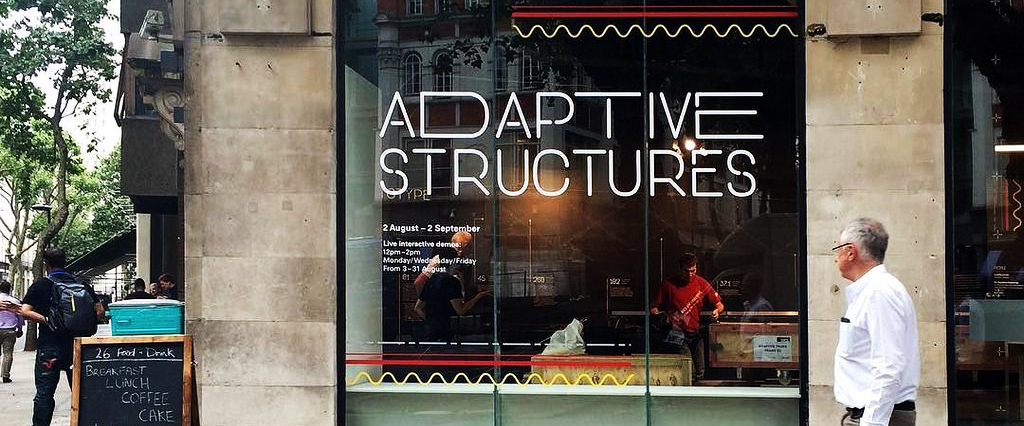

Minimum Energy Adaptive Structures are able to meet typical strength and deflection requirements using significantly less material and energy resources compared with conventional passive structures. Extensive numerical simulation has shown that the whole-life energy could be reduced by up to 70% for slender structures. Experimental testing has been carried out on an ultra-slender 6m (length) x 0.8m (width) x 0.15m (depth) (40:1 span to depth) cantilever truss equipped with 10 linear actuators and strain gauges. This configuration can be thought of as a scaled version for the superstructure of a tall tower. The structural shape can be controlled in real-time to reduce deflections and thus to maintain serviceability under loading. The control system achieves identification of the response of the structure (i.e. stress and displacements) with no predetermined knowledge of the external loading. Actuator commands are obtained by combining physics-based control with machine learning. Data gathered from experimental tests validated key assumptions and numerical predictions. This prototype adaptive structure has been exhibited internationally in key institutions and it has been adopted for further research at the Institute for Lightweight Structures and Conceptual Design of University of Stuttgart since October 2018.

The ability to reduce deflections through active control enables new designs such as super slender high-rise buildings, bridges, and self-supporting roof systems. High-rise and slender buildings could particularly benefit from this approach, providing an attractive option for urban planners to optimize space in high-density cities. The combination of low energy requirement (or carbon equivalent) and super-slender design is unique in structural engineering, thereby creating high impact potential for the built environment and society as a whole.

Acknowledgments

Gennaro Senatore has led this research during his doctorate at University College London and subsequently as a research associate at the Swiss Federal Institute of Technology (EPFL) in Lausanne. This work has been generously funded by the Engineering and Physical Sciences Research Council (EPSRC), Institution of Civil Engineers (ICE), Expedition Engineering, and Swiss National Science Foundation.

Team

Research Lead:

Gennaro Senatore

Collaborators:

Philippe Duffour, Sean Hanna | University College London

Chris Wise, Pete Winslow | Expedition Engineering

Arka Reksowardojo, Yafeng Wang, Ian Smith | Swiss Federal Institute of Technology (EPFL)

Publications

Exhibitions

</div>

Related Projects

All-In-One Structure-control Topology Synthesis

Structural Adaptation through Shape Morphing

Vibration Control through Variable Stiffness and Damping Structural Components